Remote Temperature Monitoring

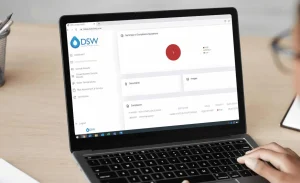

DSW’s Remote Temperature Monitoring system, powered by RTM 360, gives you real-time visibility of your water systems, without the need for manual checks. Using discreet wireless sensors and a secure cloud-based dashboard, you can monitor temperatures across your entire estate, 24/7.

This means faster responses, fewer site visits, and complete confidence in your compliance with ACoP L8 and HSG274.

Why Choose DSW Remote Monitoring?

- Real-time monitoring: Instant alerts if temperatures move outside safe limits.

- Seamless installation: Fitted quickly, with no downtime to your water systems.

- Accurate, continuous data: Long-life wireless sensors provide round-the-clock readings.

- Hassle-free: No disruption to daily operations, no clipboard checks, no missed readings.

- Compliance made simple: Instant proof of system safety and audit-ready reporting.

- Data you own: Securely stored, fully accessible, and easy to share with regulators or auditors.

- Smarter insights: Identify risks before they become problems.

- Lower costs, greener footprint: Reduce manual checks, save energy, and cut waste.

- Scalable: Whether you manage one building or a nationwide estate, the system grows with you.

- Flexible options: White label and custom branding available.

Monitor smarter. Manage better. Stay compliant.

Remote monitoring helps facilities teams, estates managers, and duty holders stay one step ahead of Legionella risks and compliance demands, while saving time, money, and resources.

DSW customers are able to take advantage of our cloud-based customer compliance portal DSW 360 SD-PTL to easily monitor any noncompliances.